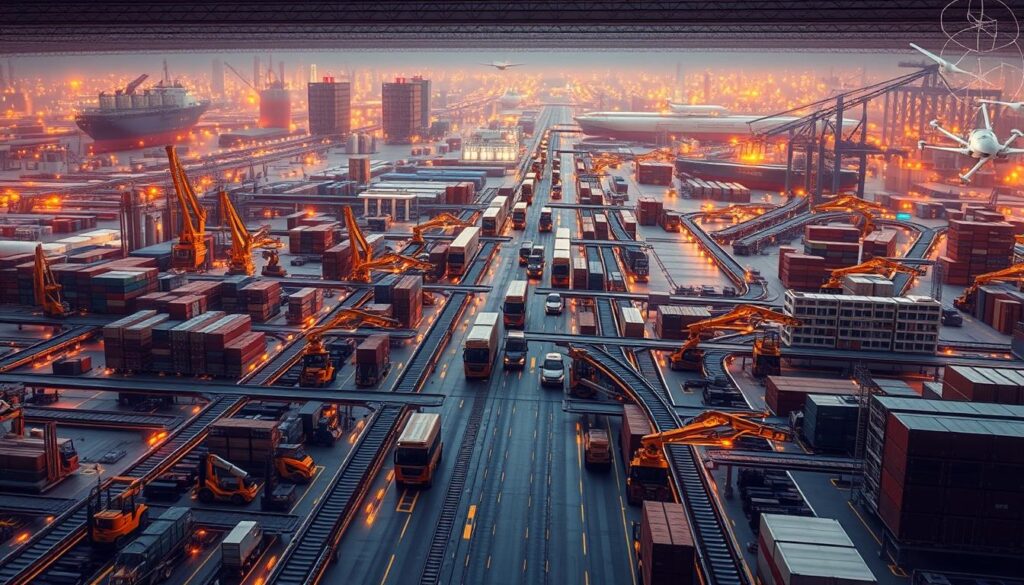

Supply chain management is vital for global trade. It’s a complex network moving products from makers to buyers. This strategic approach can determine a business’s success in today’s fast-paced market.

Efficiency is crucial in supply chain management. Coca-Cola produces 95% of their drinks in the countries where they’re sold. This smart move cuts transportation costs and speeds up distribution.

Zara, the fashion leader, showcases rapid production. They can go from design to store shelves in just two weeks. This demonstrates the power of swift manufacturing and distribution.

Logistics is key in supply chain operations. It’s about moving goods smartly, not just moving them. Walmart uses advanced systems to predict demand and maintain optimal stock.

This approach helps them stay competitive in retail. Effective supply chain management can save companies up to 30%. Advanced tech in logistics can boost efficiency by 40% through automation.

These improvements directly impact a company’s profits. They also enhance customer satisfaction. Data analytics plays a crucial role in these advancements.

Key Takeaways

- Supply chain management is crucial for global trade and business efficiency

- Effective logistics can reduce costs by up to 30% and improve efficiency by 40%

- Companies like Coca-Cola and Zara showcase successful supply chain strategies

- Advanced technologies play a key role in modern supply chain management

- Efficient supply chains can lead to faster production cycles and improved customer satisfaction

What Is Supply Chain

Supply chain management drives modern business operations. It covers the flow of goods, services, and information from suppliers to consumers. Grasping supply chain basics is vital for businesses to boost efficiency.

Definition and Basic Concepts

A supply chain links organizations, people, and resources in product or service creation. It begins with raw material sourcing and ends with customer delivery. This system includes procurement, manufacturing, warehousing, and distribution stages.

Core Components of Supply Chain

The core components of a supply chain include:

- Suppliers: Provide raw materials or components

- Manufacturers: Transform raw materials into finished products

- Distributors: Move products from manufacturers to retailers

- Retailers: Sell products to end consumers

- Customers: Final recipients of the products or services

Supply Chain Network Structure

Supply chain network structure organizes relationships between different entities. It manages the flow of materials, information, and finances. An effective structure ensures smooth coordination among all supply chain parties.

“72% of supply chain executives reported a deep negative effect on their operations due to the COVID-19 pandemic, highlighting the importance of robust supply chain management.”

Grasping supply chain complexities helps businesses tackle challenges and improve operations. Mastering supply chain management can boost efficiency and customer satisfaction. It also helps companies cut costs and stay competitive.

Evolution of Supply Chain Management

Supply chain management has changed a lot since it began. The term “supply chain” appeared in the 1980s. It marked a shift from separate operations to integrated systems.

Before, suppliers, producers, and customers rarely talked. In the 1960s and 1970s, logistics tasks merged into two main jobs. These were materials management and physical distribution.

The 1990s brought more globalization and functional integration in logistics. New tech allowed better management of information, money, and goods flows.

Recent trends show more automation in supply chains, especially in distribution centers. Flat robots now move packages in automated storage systems. This change shows early logistics engineering innovations.

Inventory management systems have evolved greatly. In 1967, IBM made the first computerized inventory system. By 1975, the first real-time warehouse system was installed.

Today, supply chains use AI and machine learning. These improve forecasting, order management, and efficiency. Businesses now focus on ethical sourcing and environmental concerns.

“The evolution of supply chain management reflects a journey from local, siloed operations to global, integrated networks driven by technology and innovation.”

This progress keeps shaping logistics and inventory management. It promises even better supply chains in the future.

Understanding Supply Chain Logistics

Supply chain logistics is crucial for global trade. It’s a complex network moving goods from manufacturers to consumers. This system includes transportation, warehousing, and inventory management.

Role of Logistics in Supply Chain

Logistics connects every part of the supply chain. It controls how and when goods are made, moved, and delivered. Without it, the entire supply chain would stop working.

Key Logistics Functions

The main functions of logistics include:

- Transportation: Moving goods by road, rail, air, or sea

- Warehousing: Storing products safely and efficiently

- Inventory Management: Keeping track of stock levels

- Order Fulfillment: Preparing and shipping customer orders

These functions ensure products reach customers on time and in good condition. Effective logistics management can boost overall profitability by 30%.

3PL and 4PL Services

Many companies use third-party (3PL) or fourth-party (4PL) providers for logistics. These services handle various supply chain aspects, from transportation to warehousing. This allows businesses to focus on their main operations.

Using 3PL or 4PL services can improve supply chain efficiency. Companies can meet customer demands better and gain a market edge.

| Logistics Function | Potential Improvement |

|---|---|

| Delivery Speed | Up to 50% faster |

| Freight Costs | 15% reduction |

| Warehousing Costs | 25-30% savings |

A good logistics strategy can greatly improve supply chain performance. It helps companies meet customer needs and stay competitive in the market.

Supply Chain Strategy and Planning

Supply chain management optimizes goods flow from source to customer. A strong strategy boosts business performance in changing markets. Strategic planning enhances operations and cuts costs significantly.

Strategic Planning Process

Strategic planning focuses on long-term network design and tech investments. Effective strategies can cut operational costs by 20%. Simulation tools test supply chain resilience, potentially reducing time-to-market by 25%.

Operational Planning

Operational planning handles medium-term decisions like production and inventory. Data-driven inventory management balances stock with demand. AI can boost demand forecasting accuracy by 20-50%.

Advanced tech can reduce distribution center storage needs by 30%. This improvement streamlines operations and cuts costs.

Tactical Decision Making

Tactical decisions address daily operations and problem-solving. Effective sales and operations planning aligns departmental goals. This alignment can increase service level agreement fulfillment by 20%.

Streamlined processes can improve production cycles by 30%. Faster cycles lead to quicker order fulfillment and customer satisfaction.

Aligning supply chain strategies with business goals drives competitive advantage. This approach improves supplier relationships, procurement, and overall supply chain performance.

| Planning Level | Focus | Potential Impact |

|---|---|---|

| Strategic | Long-term decisions | 20% reduction in operational costs |

| Operational | Medium-term decisions | 30% reduction in storage requirements |

| Tactical | Day-to-day operations | 20% increase in service level fulfillment |

Inventory Management Systems

Inventory management is vital for supply chain operations. It’s the foundation of efficient logistics and key to supply chain success. Modern businesses now use advanced systems to streamline their processes.

Bar code and RFID systems have transformed inventory tracking. These technologies offer real-time stock visibility, boosting warehouse efficiency. They link products with multiple data points, from supplier info to stock levels.

AI and IoT are reshaping inventory management. AI systems help quickly adjust logistics, materials, and warehouse operations. IoT sensors provide better insight into inventory location and status.

Accurate demand forecasting is crucial for effective inventory management. Companies use big data to meet production demands and speed up fulfillment. This approach helps balance inventory, avoiding stockouts and excess stock.

| Inventory Tier | Characteristics | Management Approach |

|---|---|---|

| A | High turnover/value items | Highest risk of stock-outs, strict management |

| B | Moderate movement items | Less stringent management |

| C | Slow-moving items | Infrequent counts |

Good inventory management strategies boost delivery times and customer satisfaction. They also cut operational costs. The global supply chain market hit $37.5 billion in 2023.

Efficient inventory systems are crucial in today’s logistics landscape. They help businesses stay competitive and meet customer demands effectively.

Transportation and Distribution Networks

Modern logistics rely on transportation networks and distribution channels. These systems ensure products reach consumers efficiently. They play a key role in supply chain management.

Transportation Modes

Various transportation modes meet different logistics needs. Trucks dominate road freight, while trains offer cost-effective long-distance transport. Air freight provides speed for time-sensitive goods. Ships handle large volumes for international trade.

Distribution Center Operations

Distribution centers are hubs in logistics networks. Walmart has 190 facilities covering 924 million square feet, larger than Manhattan. These centers use advanced systems for inventory management. They streamline the supply chain process.

Last-Mile Delivery Solutions

Last-mile delivery faces unique challenges in urban areas. Companies explore innovative solutions like drones and autonomous vehicles. Amazon’s network of 1,215 distribution facilities supports its last-mile delivery strategies.

| Aspect | Without Distribution Plan | With Distribution Plan |

|---|---|---|

| Order Fulfillment Time | 10 days | 2 days |

| Customer Satisfaction | Lower | Higher |

| Operational Efficiency | Reduced | Improved |

Effective networks greatly impact business performance. Companies with formal plans fulfill orders five times faster. This leads to increased customer satisfaction. It also improves operational efficiency.

Supply Chain Technology and Innovation

Technology is revolutionizing supply chain management. It’s driving efficiency and transparency to new heights. The digital transformation is reshaping traditional processes, enabling unprecedented visibility and responsiveness.

Internet of Things (IoT) sensors are game-changers in the industry. They can slash transportation costs by 10-30%. These sensors also boost inventory accuracy by 20-50%.

Artificial Intelligence (AI) is another powerhouse in supply chain innovation. AI-powered predictive analytics can reduce inventory levels by 20-30%. It also improves service levels up to 90%.

Blockchain technology enhances supply chain security and transparency. It can cut costs by 5-10% and speed up transactions. Blockchain provides an unalterable record of goods’ origins and journeys.

- Robotic process automation (RPA) can boost operational efficiency by up to 40%

- 3D printing reduces lead times by 75% and material costs by up to 90%

- Augmented reality (AR) increases productivity by 25-30% in supply chain operations

The future of supply chain management lies in embracing technological innovations. Companies that leverage these tools are better equipped. They can create resilient, agile supply chains capable of adapting to changing conditions.

Demand Forecasting and Planning

Demand forecasting is vital for supply chain management. It helps businesses predict customer needs and optimize inventory. Accurate forecasting prevents costly stockouts and overstock situations.

Companies can streamline operations by anticipating future demand. This leads to better resource allocation and improved customer satisfaction.

Forecasting Methods

Supply chain managers use various methods to predict demand. These include:

- Time series analysis

- Causal inferences

- Machine learning

- Collaborative planning, forecasting, and replenishment (CPFR)

Each method has unique strengths for different scenarios. Time series analysis suits stable markets. Machine learning excels in complex, rapidly changing environments.

Demand Planning Tools

Modern demand planning tools use advanced analytics and real-time data. They often integrate with ERP systems for a comprehensive supply chain view.

Popular features include:

- Predictive analytics

- Scenario planning

- Automated data collection

- Real-time dashboards

Sales and Operations Planning

Sales and Operations Planning (S&OP) aligns demand forecasts with supply capabilities. This process ensures all departments work towards the same goals.

A well-executed S&OP process can lead to:

- Reduced inventory costs

- Improved customer service

- Increased supply chain agility

| Benefit | Impact |

|---|---|

| Improved Forecast Accuracy | 15-25% reduction in inventory costs |

| Enhanced Customer Service | 5-10% increase in on-time deliveries |

| Increased Supply Chain Agility | 20-30% faster response to market changes |

Effective demand forecasting and planning boost supply chain performance. This gives businesses a competitive edge in the market.

Companies can reduce costs and improve customer satisfaction through these strategies. The result is a more efficient and responsive supply chain.

Procurement and Supplier Management

Procurement and supplier relationships are vital for effective supply chain management. These elements drive organizational success in today’s complex business world. They help companies become more resilient and competitive.

The procurement process involves several key steps. It starts with identifying needs and ends with managing supplier relationships. Organizations that excel in procurement often see significant benefits.

Strategic sourcing and negotiation can lead to substantial cost savings. Operational budgets can be reduced by 5-15% through these methods. This makes procurement a crucial area for businesses to focus on.

Supplier relationship management is equally crucial. Strong partnerships can result in better terms and improved collaboration. This can lead to a 10-20% reduction in costs.

Additionally, service quality and delivery reliability can increase by up to 30%. These improvements significantly impact a company’s overall performance and customer satisfaction.

Risk management is a critical aspect of procurement. In 2023, 96% of US companies faced fraud attempts. Vigilance is essential to protect against these threats.

Implementing continuous account validation helps mitigate risks. Robust risk assessments are also crucial. These measures safeguard companies from potential financial and reputational damage.

Sustainability is becoming increasingly important in procurement. 82% of organizations believe sustainable practices enhance brand reputation and customer loyalty. Ethical sourcing benefits the environment and contributes to long-term business success.

Technology and data analytics are reshaping procurement processes. Organizations using these tools report increased efficiency of up to 25%. Better decision-making and spending insights drive this improvement.

Digital transformation is key to staying competitive. It helps businesses adapt to the fast-paced modern environment. Embracing these changes can lead to significant advantages in the marketplace.

Warehouse Management and Operations

Warehouse management is vital in logistics and inventory control. It ensures smooth goods flow, cuts costs, and boosts customer satisfaction. Efficient operations are key to success in this field.

Warehouse Design

Smart warehouse design boosts space use and workflow. It can reduce costs by 15-30% compared to on-site storage. Good location near transport hubs can cut shipping costs by 20%.

Storage Systems

Modern storage systems improve inventory management. Real-time tracking cuts excess stock by 25%. Automated storage and retrieval systems (AS/RS) increase efficiency.

A Warehouse Management System (WMS) boosts inventory accuracy. It can reduce stock issues by 50%.

Order Fulfillment Processes

Smooth order fulfillment is crucial for happy customers. Well-run warehouses achieve 99% delivery accuracy. Companies using automated solutions report 98% fulfillment rates.

WMS adoption increases picking productivity by 20-30%.

| Benefit | Improvement |

|---|---|

| Operational Cost Reduction | 20% |

| Inventory Accuracy | 50% reduction in errors |

| Customer Satisfaction | 30% increase |

| Fulfillment Rate | 98% or higher |

Smart warehouse management is changing logistics. E-commerce growth means 80% of warehouses must adapt to faster delivery needs. Green practices will rise by 60%.

Focus on waste reduction and energy savings of 30% is expected in the next ten years.

Supply Chain Risk Management

Supply chain risk management is vital in our global economy. It identifies and addresses vulnerabilities in procurement and logistics. Effective strategies boost business continuity and competitiveness.

During COVID-19, supply chain disruptions rose by over 90%. This surge underscores the need for strong risk management. Companies using these strategies have cut costs by up to 20%.

Supply chains face operational, financial, geopolitical, and environmental risks. The 2011 Japan earthquake disrupted automotive and electronics sectors worldwide. The US-China trade war in 2019 forced businesses to rethink sourcing.

- Natural disasters disrupt approximately 20% of global supply chains annually

- 60% of organizations rely on just three suppliers for crucial components

- 75% of companies lack visibility into their entire supply chain

To build resilience, companies should diversify suppliers and create backup plans. They should also use technology for real-time risk monitoring. Diversified sourcing can reduce supply disruption risks by up to 25%.

Investing in supply chain analytics can improve risk assessment accuracy by 25%. Effective risk management is key to stability in today’s complex business world.

Sustainable Supply Chain Practices

Supply chain management is evolving to embrace sustainability. Companies now balance economic goals with environmental and social responsibilities. This shift reshapes how businesses approach logistics and manage their supply chains.

Environmental Considerations

Environmental sustainability in supply chains aims to reduce carbon emissions and minimize waste. Many multinational corporations set long-term sustainability goals. They encourage their suppliers to adopt eco-friendly practices.

Social Responsibility

Social responsibility addresses ethical sourcing, fair labor practices, and community engagement. The UK’s Modern Slavery Act requires companies to report on preventing modern slavery. California’s Transparency in Supply Chains Act has similar requirements.

Green Logistics

Green logistics reduces the environmental impact of transportation and warehousing. Over 85,000 businesses use Sedex to map their supply chains. This trend drives innovation in circular economy models and reverse logistics.

| Aspect | Impact | Action |

|---|---|---|

| Environmental | Ecosystem damage, worker health issues | Reduce emissions, minimize waste |

| Social | Labor rights violations, community disruption | Ethical sourcing, fair labor practices |

| Economic | Worker turnover, skill loss | Improve working conditions, secure employment |

Sustainable supply chain practices offer challenges and opportunities. Companies can improve their environmental performance and social impact. This approach leads to long-term business success and a healthier planet.

Global Supply Chain Management

Global supply chain management is crucial for business success in our connected world. Companies use international channels to cut costs and expand markets. The market value is expected to grow from $18.7 million in 2020 to $52.6 million by 2030.

Global supply chains can use up to 85% of a company’s revenue. Sourcing from countries with cheaper labor or resources lowers production costs. This model benefits various industries like food, mining, and electronics.

Effective logistics management is key for success in international markets. Strategic warehouse placement near cities reduces delivery distances and impacts costs. E-commerce often uses third-party logistics to manage shipping expenses.

Global supply chain management covers six main areas:

- Logistics management

- Competitor orientation

- Customer orientation

- Supply-chain coordination

- Supply management

- Operations management

Successful management requires compliance with international regulations and adaptability to challenges. These include labor constraints, geopolitical turmoil, and environmental disasters. Companies can reduce lead times and costs by focusing on these aspects.

This approach also enhances customer satisfaction in the competitive global marketplace. It allows businesses to stay ahead and meet customer demands efficiently.

Supply Chain Analytics and KPIs

Data-driven decisions are vital in supply chain management. Advanced tech offers powerful ways to analyze supply chains. Let’s explore key metrics, analysis tools, and reporting systems for modern inventory management.

Performance Metrics

Key performance indicators (KPIs) measure supply chain efficiency. The Perfect Order KPI assesses on-time, in-full, and damage-free delivery, plus accurate documentation.

The Cash-to-Cash Cycle Time shows days between paying suppliers and receiving customer payments. Shorter times indicate better supply chain efficiency.

Data Analysis Tools

Supply chain managers use advanced tools to gain insights. Inventory management systems track turnover ratios and days of supply.

The Inventory Turnover Ratio shows how efficiently a company sells stock. It’s calculated as Cost of Goods Sold divided by Average Inventory.

Data analysis also helps in demand forecasting. This allows businesses to optimize their logistics operations.

Reporting Systems

Effective reporting is crucial for understanding supply chain data. Real-time dashboards update critical metrics every 15 minutes.

These systems track KPIs like the Fill Rate, which measures order fulfillment efficiency. Companies can identify areas for improvement using these tools.

By leveraging reporting tools, businesses can reduce costs and boost customer satisfaction. This leads to enhanced supply chain and logistics processes.